Specification

- उपयोग

- Industrial

- बिजली की आपूर्ति

- 24 V DC

- एप्लीकेशन

- For Measurement of Oxygen, Combustible & Toxic Gas Detection

- रंग

- Yellow Metal

- मशीन का वजन

- किलोग्राम (kg)

Trade Information

- Minimum Order Quantity

- 1 Number

- आपूर्ति की क्षमता

- प्रति महीने

- पैकेजिंग का विवरण

- Standard Packaging

- मुख्य घरेलू बाज़ार

- प्रमाणपत्र

- CE

About

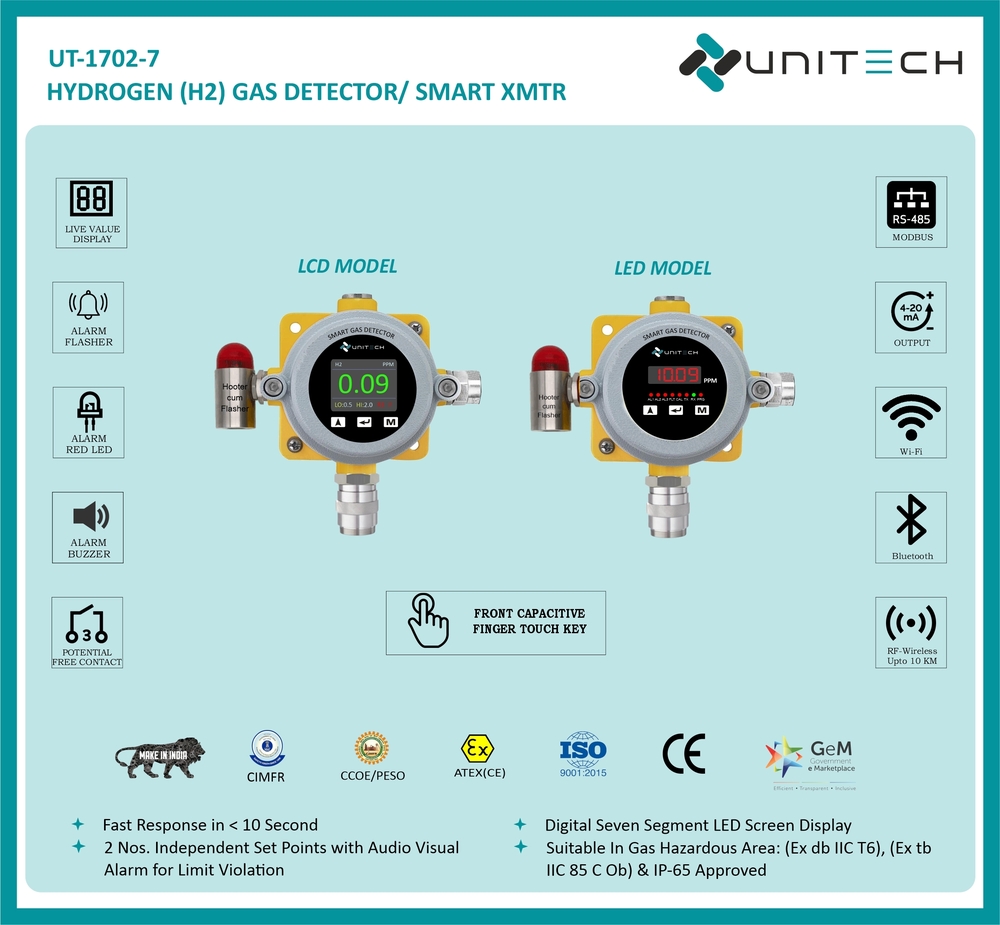

Gas Detector Can Measure smallest leak / presenceof Oxygen, Combustible, Toxic and Volatile Organic Compounds (VOC).

Pluggable gas sensor module for easyreplacement and maintenance.

Capable of detecting down to PPM, %V/V,%LEL, mg/m3.

Standard 4-20mA signal output withconfigurable range.

Modbus RTU multi-drop RS485 / RF-Wireless /Wi-Fi / Bluetooth Communication Port Available.3 level Password Protection onfor Configuration on and Calibration.

Display Indication for Sensor Open, OverRange & Sensor Change or Replace.

Process Parameter High and Low LED StatusIndication with Audible Buzzer / Flasher for Limit Violation.

Accurate Gas Detection for Industrial Environments

The Hydrogen Gas Detector provides reliable detection and measurement of oxygen, hydrogen, and other hazardous gases across industrial settings. Its robust build and sharp sensitivity help safeguard workers by quickly identifying potentially dangerous concentrations. The devices vivid yellow metal casing enhances visibility, supporting prompt maintenance and emergency interventions.

Flexible Power and Installation Options

Operating on a stable 24 V DC power supply, this detector can be seamlessly integrated into existing industrial infrastructure. Its lightweight construction (2 kg) allows for versatile installation, whether wall-mounted or portable, reducing setup complexities and providing operational flexibility for industrial users.

FAQs of Hydrogen Gas Detector:

Q: How does the Hydrogen Gas Detector work in detecting combustible, toxic, and oxygen gases?

A: The detector utilizes advanced sensor technology to continuously monitor air quality for the presence of hydrogen, oxygen, and other hazardous gases. When potentially dangerous levels are detected, it triggers audible and visual alarms to alert personnel, ensuring rapid response.Q: What are the main benefits of using this yellow metal hydrogen gas detector in industrial settings?

A: Its key benefits include enhanced safety through early gas detection, robust design for harsh environments, bright coloration for easy identification, and reliable performance with a steady 24 V DC power supply.Q: When should the Hydrogen Gas Detector be calibrated or serviced in industrial applications?

A: Regular calibration is recommended every six months, or based on manufacturer guidelines, to maintain accuracy. Additional servicing may be necessary after exposure to high gas concentrations or following routine inspections.Q: Where can this gas detector be installed within an industrial facility?

A: The detector can be installed in any area where monitoring gases is essential, such as production floors, storage rooms, control centers, or near gas pipelines. Its flexible design accommodates both fixed and portable placements.Q: What is the process for exporting or supplying this detector in India?

A: As an exporter, manufacturer, supplier, and trader, the process involves fulfilling industrial orders according to client specifications, adhering to safety and quality standards, and ensuring prompt delivery throughout India.Q: How is the usage of the detector tailored for industrial safety applications?

A: Industries employ this device for continuous surveillance of hazardous gas levels, integrating it into safety protocols to initiate alarms and facilitate evacuation or corrective measures in case of detected risks.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in गैस डिटेक्टर Category

क्लोरीन गैस डिटेक्टर

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1

माप की इकाई : नंबर

मूल्य की इकाई : नंबर

एप्लीकेशन : सीएल 2 गैस का पता लगाना

बिजली की आपूर्ति : 24 वी डीसी

LEL गैस डिटेक्टर

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1

माप की इकाई : नंबर

मूल्य की इकाई : नंबर

एप्लीकेशन : Lab

बिजली की आपूर्ति : Electric